Application: Crane Cables as connecting and control cables for lifts or cranes, also used for various kinds of electric installation in dry or wet environments.https://www.bofan-cable.com/product-category/elevator-cable-crane-cable/

Design requirements:

√ High wear resistance: the cable sheath must be able to withstand the ore friction for a long time without damage.

√ High tensile strength: in mining, the use length of cable is relatively long, and the ground friction is very large. This requires the cable to have a strong tensile strength to avoid core broken.

√ Torsional resistance: the cable needs long-distance drag in the underground roadway, and often turns in the roadway. This is bound to cause the torsion of the cable, the strong torsion resistance avoids the sheath crack.

√ Water resistance and corrosion resistance: in underground mining, there may be water or corrosive liquid, which requires the cable to have enough waterproof and corrosion resistance.

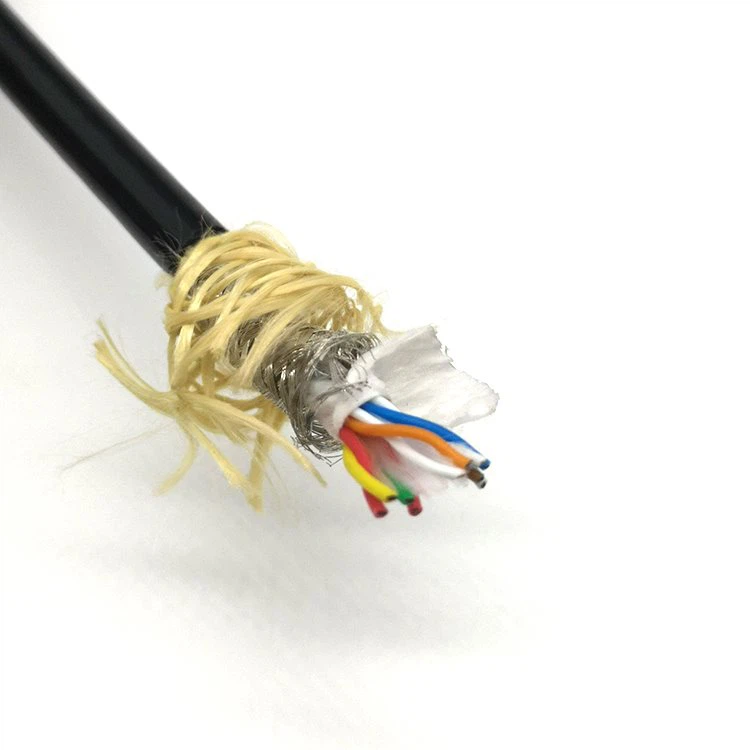

Product Structure:

Conductor: Stranded oxygen-free copper wire for flexiblility and corrosion resistance.

Insulation: PVC

Cores: 2-60 cores. Color distinction/coding distinction, yellow-green earth core.

Strength member: Special high quality aviation steel wire, tensile fiber.

Inner jacket: TPU/NBR

Outer jacket: PUR (Customized color)

Temperature range: Fixed installation: -40℃ -90℃, Mobile installation: -30℃ -90℃

Minimum bending radius: 7.5D

Voltage: 600/1000V