Application:Underwater Composite Cable also called watertight fiber optic composite flexible cables or composite cable is suitable as connecting cables for underwater robots and other equipment. And they can also used as tether cables and umbilicals for subsea operations, marine monitoring, oil exploration, underground pipelines, and underground operations.

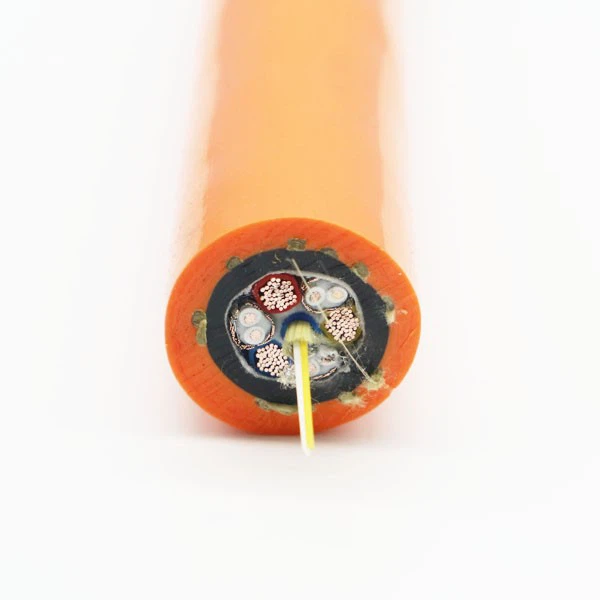

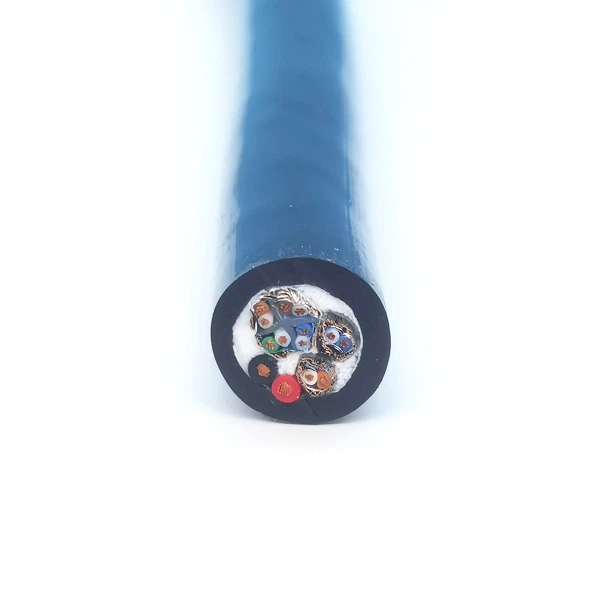

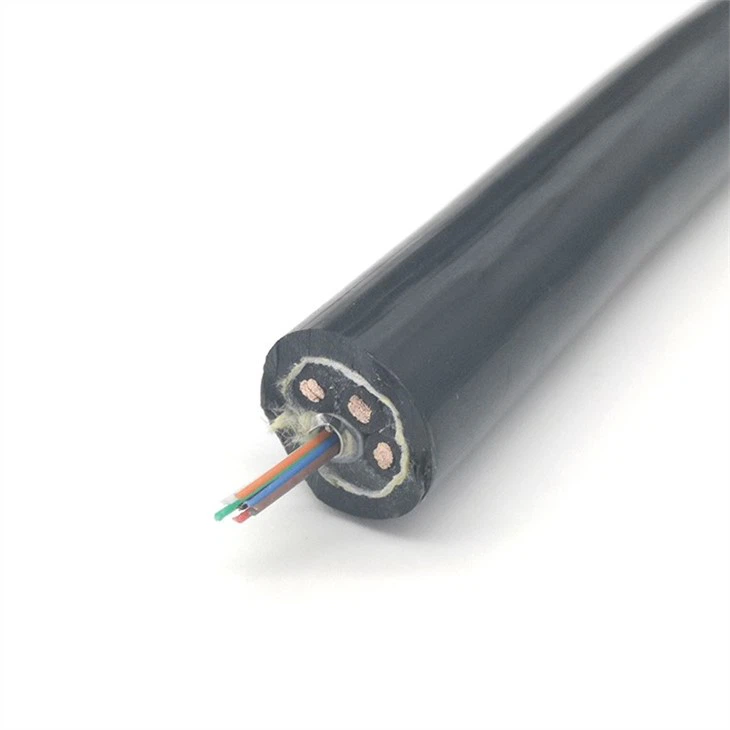

Cable structure:

– 3 core 6.0mm2 (10AWG) for power supply

– 3 pair 0.34mm2 (22AWG) for signal transmission

– 2 core SM fiber optic

Conductor: Strand oxygen-free copper wire, in line with VDE0295 CLASS6 standard

Insulation: PE/FEP

Fiber armor: Steel tape armor

Shield: Tinned copper braided (density ≥85%)

Wrapping: Wrapping with non-woven fabric

Inner sheath: PUR (Black)

Strength member: Kevlar braided (200kg)

Outer sheath: PUR (Orange)

Do you know how to make watertight fiber optic composite cables ? This cable is an organic combination of power transmission and high-performance signal transmission of optical cable, with strong information throughput and high-speed data transmission. The underwater composite cable or photoelectric composite cable uses Kevlar as the tensile strength member, and the breaking tension can reach 1T, which prevents the cable from being damaged due to excessive tensile force during the retraction process; The glue injection machine is used to continuously and automatically fill the water-blocking glue to meet the requirements of horizontal and vertical watertightness and floating. It has the characteristics of high tensile strength, flexural resistance, oil resistance and aging resistance. It can be reused and meets the requirements of a new generation of underwater equipment.http://www.bofan-cable.com