Why Spiral cable can be used for bicycles?

Spiral cable also used for Bicycle, do you know it ? With the improvement of people’s living standards, more and more people like to ride, the bicycle is no longer just a means of transportation, more is a fitness equipment. Therefore, our demand for spring cable and quality requirements are becoming higher and higher. Please see the follow video about our spring cable that used in the bicycle of our customer. https://www.youtube.com/watch?v=HjTgXj_6mUc

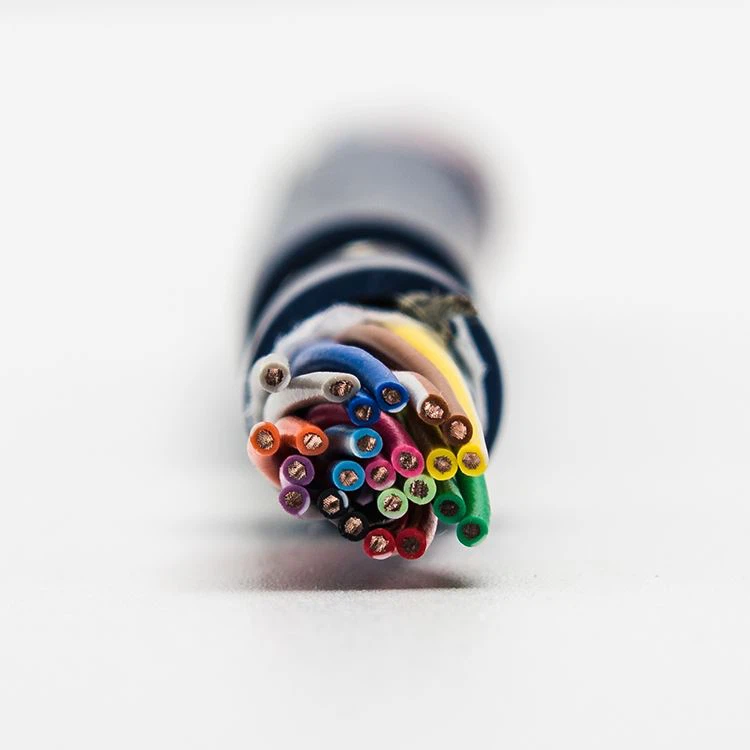

Spiral cable also called spring cable or Coiled cable, we use these cables in bicycles, primarily for brake systems.

The use of spring cable in bicycle brakes allows for better performance and durability. The spring cable acts as a return mechanism that pulls the brake caliper or arm back to its original position after the brake lever is released. This ensures that the brake pads are not left pressing against the rim, which can cause wear, heat buildup, and friction.

We commonly used the spring cable in cantilever, V-brakes, and other types of rim brakes on bicycles. The spring cables can also be easily adjusted to ensure proper tension, which is critical for consistent and reliable braking.

It’s worth noting that some bicycle brake systems may use other types of return mechanisms, such as coil springs or elastomer inserts. The specific design and choice of return mechanism can depend on various factors, including the type of brake system and the desired level of performance.https://youtu.be/LjJTgRfVz0Q?si=OfFcz5cdkRbzHYQm

The performance characteristics of the spiral cable used in bicycles

The performance characteristics of the spiral cable used in bicycles can vary depending on the specific type and quality of the wire. However, here are some general performance characteristics:

- Strength: Spiral cable used in bicycles is typically required to have high tensile strength to withstand the stress and load applied during cycling.

- Flexibility: Spiral cable needs to be flexible enough to absorb and distribute shocks and vibrations, enhancing the overall ride comfort.

- Fatigue resistance: Cycling involves repeated cycles of stresses and strains, so the spring wire should have good fatigue resistance to maintain its performance over time.

- Elasticity: The wire should possess good elasticity to enable it to return to its original shape after being deformed, ensuring efficient energy transfer and responsiveness.

- Corrosion resistance: Since bicycles are exposed to various weather conditions and potential moisture, the spring wire should have good corrosion resistance to maintain its structural integrity.

- Durability: The wire should be durable enough to withstand prolonged use and external impacts without significant degradation in performance.

These characteristics contribute to the overall performance, durability, and reliability of the spring wire used in bicycles. It is important to note that different bicycles may use different types of spring wire with varying performance specifications to match their specific requirements.

Custom 3 Core Spring Cable