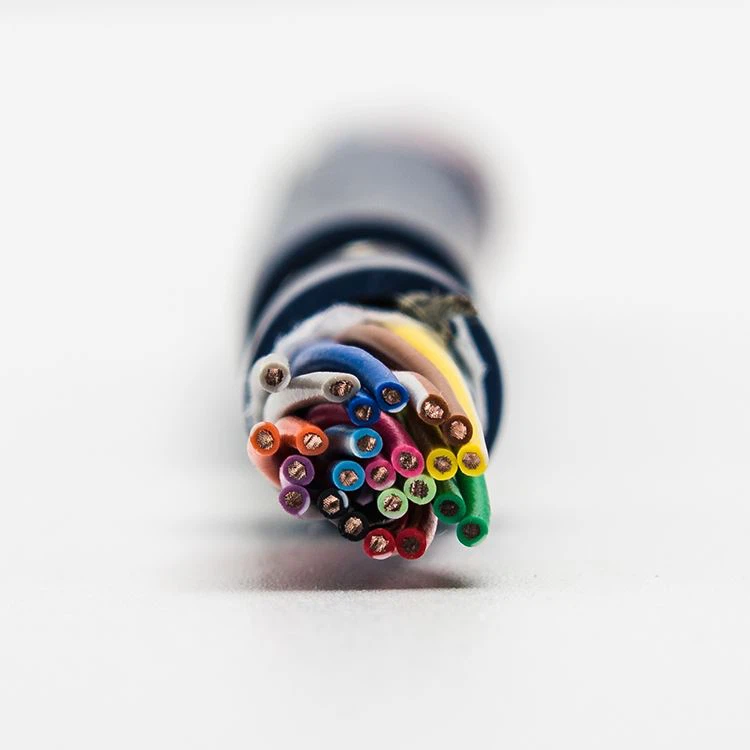

Relationship between elasticity and outer diameter

The spring force of a wire is related to its physical characteristics, such as its diameter, length, and material properties. In the case of a spring wire with a larger outer diameter, the spring force may be less due to several factors.

One factor is the change in the wire’s stiffness or spring constant. The spring constant is a measure of how easily the wire can be stretched or compressed. In general, a larger diameter wire has a higher stiffness or spring constant. Means it requires more force to stretch or compress it compared to a smaller diameter wire. Therefore, a larger diameter cable may have a lower spring force for the same amount of deformation.

Another factor is the change in the total length of the wire when it is stretched or compressed. When a spring cable is deformed, its length changes according to Hooke’s law, which states that the force applied is directly proportional to the displacement. For a larger diameter wire, the change in length per unit deformation is relatively smaller compared to a thinner wire. Therefore, a larger diameter wire may have less spring force for the same amount of deformation due to its lesser change in length.

честные казино с быстрыми выплатами

бездепозитные бонусы казино

играть в лучшем казино на деньги

база казино с бездепозитным бонусом

онлайн казино России

casino oyunu

It’s important to note that these relationships are general tendencies and may vary depending on the specific material properties, design, and construction of the spring cable. Additionally, other factors such as the number of coils, pitch, and overall geometry of the spring also affect its performance.https://www.bofan-cable.com/product-category/spiral-cable/